In order to validate and optimize any new design, the engineer will typically build a prototype unit if doing so is economically feasible. While simulation software is often a valuable tool to use during the design process, the result of simulation is an approximation at best – since it may exclude some variables of which the engineer or programmer is unaware. The construction of an actual prototype may also point the designer towards improvements that were not obvious when considering drawings alone.

In order to validate and optimize any new design, the engineer will typically build a prototype unit if doing so is economically feasible. While simulation software is often a valuable tool to use during the design process, the result of simulation is an approximation at best – since it may exclude some variables of which the engineer or programmer is unaware. The construction of an actual prototype may also point the designer towards improvements that were not obvious when considering drawings alone.

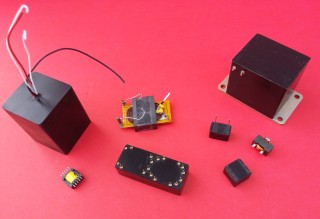

A prototype unit allows the designer to test electrical performance and mechanical and thermal attributes, as well as ease of construction. When required, a prototype may be completed to its

final production configuration for fit and test in the customer application.

US Magnetics is equipped to provide prototype units and test reports with each design submitted. Units up to around 500 pounds are constructed at our own facility. Due to handling limitations, units over 500 to approximately 1500 pounds are constructed using our equipment and personnel at an off-site facility.

Our Statement of Work submitted with each proposal will typically include a single prototype unit – and will describe whether it is to be submitted in its production configuration. We will be pleased to meet your own specific requirements.